THE CHALLENGE

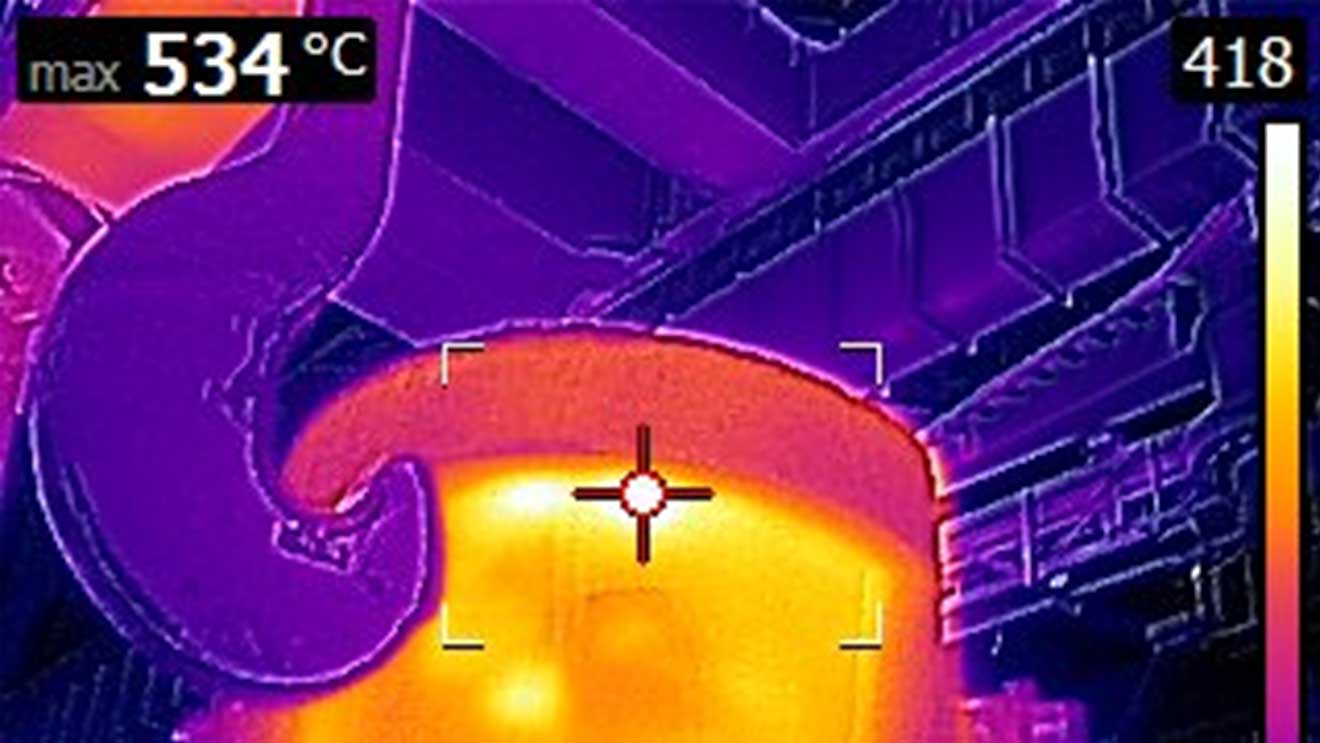

The challenge was to enhance ladle lining stability and safety in secondary steelmaking, addressing hot spots and steel penetration issues.

In secondary steelmaking practices, maintaining ladle lining stability and safety is crucial. Ladle breakouts pose significant risks, including the loss of molten metal and potential injury to workers.

Traditional monitoring practices were insufficient in addressing these issues, leading to frequent ladle failures and increased operational costs.

The need for a more robust solution to enhance ladle lining stability and safety became evident, prompting a comprehensive review of existing practices and the exploration of innovative approaches to improve the performance and reliability of the ladle lining.

THE SOLUTION

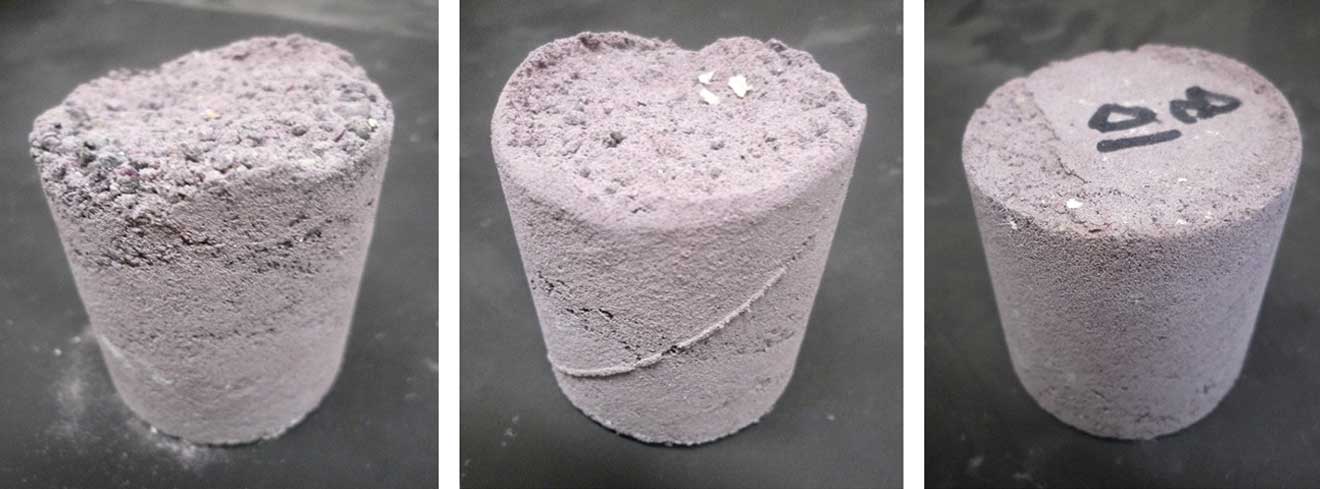

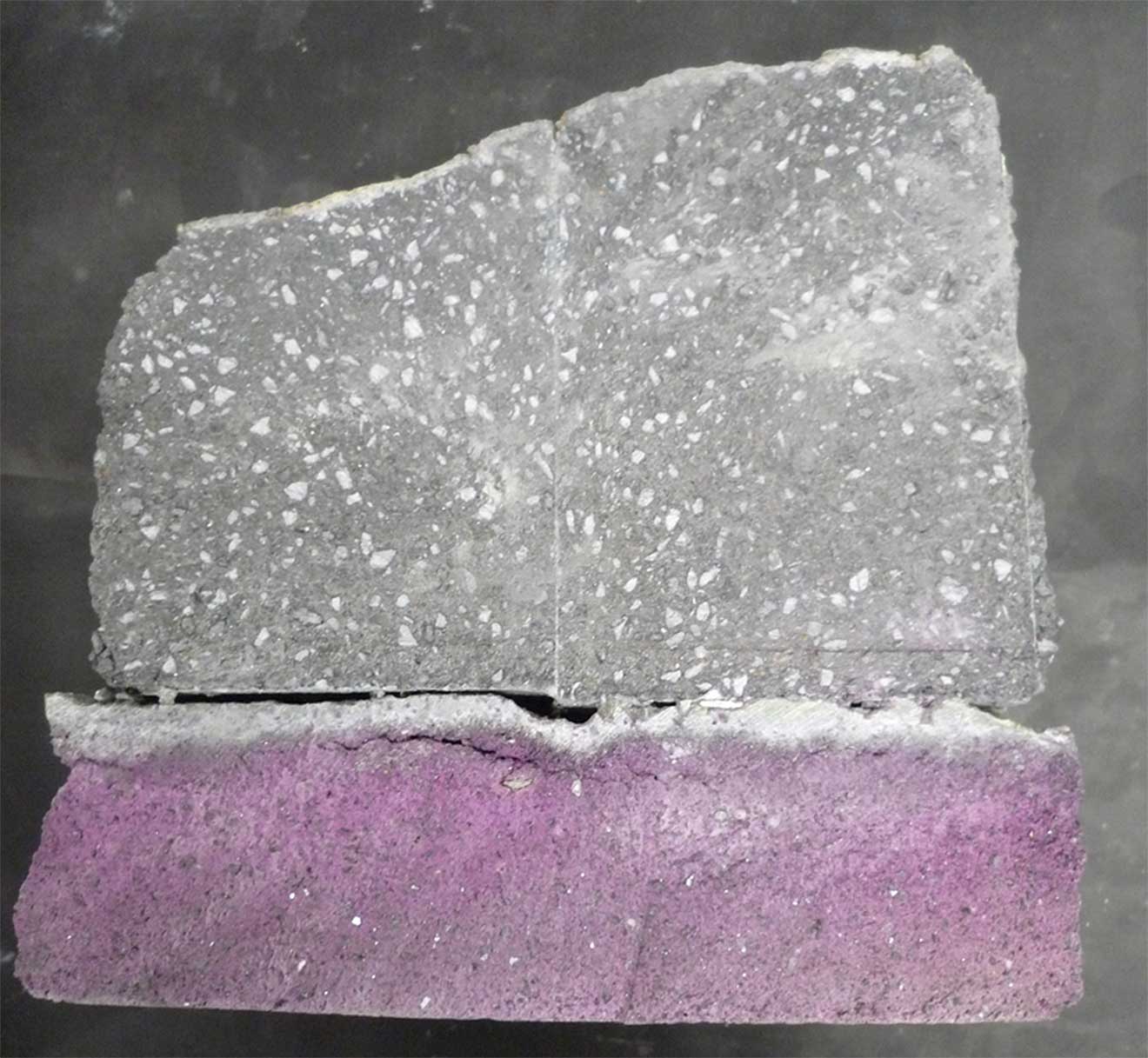

The solution involved the introduction of intermediate granular backfill to enhance ladle lining stability and safety.

This approach focused on improving the compaction and time at temperature of the backfill lining.

Changes were made to the installation practices to ensure better performance of the backfill material.

The new method included rigorous monitoring and adjustments to the backfill composition and application techniques.

By addressing the root causes of hot spots and steel penetration, the solution aimed to provide a more stable and reliable ladle lining.

The collaborative efforts of various departments, including engineering and operations, were essential in implementing these changes and achieving the desired outcomes.

THE RESULT

The result was a significant improvement in ladle lining stability and safety, with the plant now regularly exceeding record ladle lining lives.

The implementation of the intermediate granular backfill led to significant improvements in ladle lining stability and safety.

The enhanced compaction and optimised time at temperature resulted in a more robust backfill lining, reducing the occurrence of hot spots and steel penetration.

These changes contributed to a notable increase in ladle life and reliability, minimizing the risks associated with ladle breakouts.

The improved performance of the ladle lining also led to a reduction in operational costs and downtime, as fewer ladle failures occurred.

Additionally, the plant now regularly exceeds record ladle lining lives, demonstrating the long-term benefits of the new practices.

The success of this solution demonstrated the effectiveness of the new installation practices and the importance of continuous monitoring and adjustments to maintain optimal ladle lining performance.

VALUE DELIVERED

The solution enhanced safety, reduced operational costs, and increased productivity by significantly improving ladle lining stability and reliability.

The value delivered by this solution was multifaceted. Firstly, it significantly enhanced the safety of secondary steelmaking practices by reducing the risks associated with ladle breakouts.

This improvement not only protected workers from potential injuries but also ensured the continuity of operations. Secondly, the increased ladle life and reliability translated into substantial cost savings for the company.The reduction in operational costs and downtime allowed for more efficient use of resources and improved overall productivity.

Lastly, the successful implementation of the intermediate granular backfill highlighted the importance of innovation and collaboration in addressing complex challenges, setting a precedent for future improvements in ladle lining practices.

WHAT OUR CLIENT SAID

Ex experch illores torecepe ventem lab iusamet occum ut quas maio officiate lam res conseque a ditat audipie ntibusamuste doluptati volum re offic tem venist, cus alique.

Esther Coupland | Technologist BOS Development