Our Partners

At Trent Refractories, we recognise that our success is built on the strong relationships we have with our commercial partners. Their expertise, innovation, and commitment play a crucial role in delivering high-quality products and services to our customers. We view our partners not just as suppliers or service providers, but as key contributors to our shared vision and long-term growth. Their dedication to excellence, reliability, and continuous improvement ensures that we remain at the forefront of our industry.

Collaboration is at the heart of everything we do. By working closely with our partners, we drive innovation, enhance efficiency, and create value for our customers and stakeholders. We are committed to fostering strong, transparent, and mutually beneficial relationships, ensuring sustainable success for all involved. Together, we achieve more.

CASE STUDIES

VIM Stick Casting Trial Case Study

The client needed to determine the feasibility of producing smaller diameter sticks using the VIM process..

The client, an established manufacturer of large diameter nickel super-alloy ingots using the VIM (Vacuum Induction Melting) process, faced a challenge in producing smaller diameter sticks.

They needed to determine the feasibility of this new manufacturing process.

The project required precise material development, engineering, and design of a prototype catcher box.

Additionally, the project had to be completed within a tight timeline of three weeks, which was later extended to four weeks due to unforeseen complexities. The client sought Trent Refractories' expertise to overcome these challenges and ensure the successful execution of the trial.

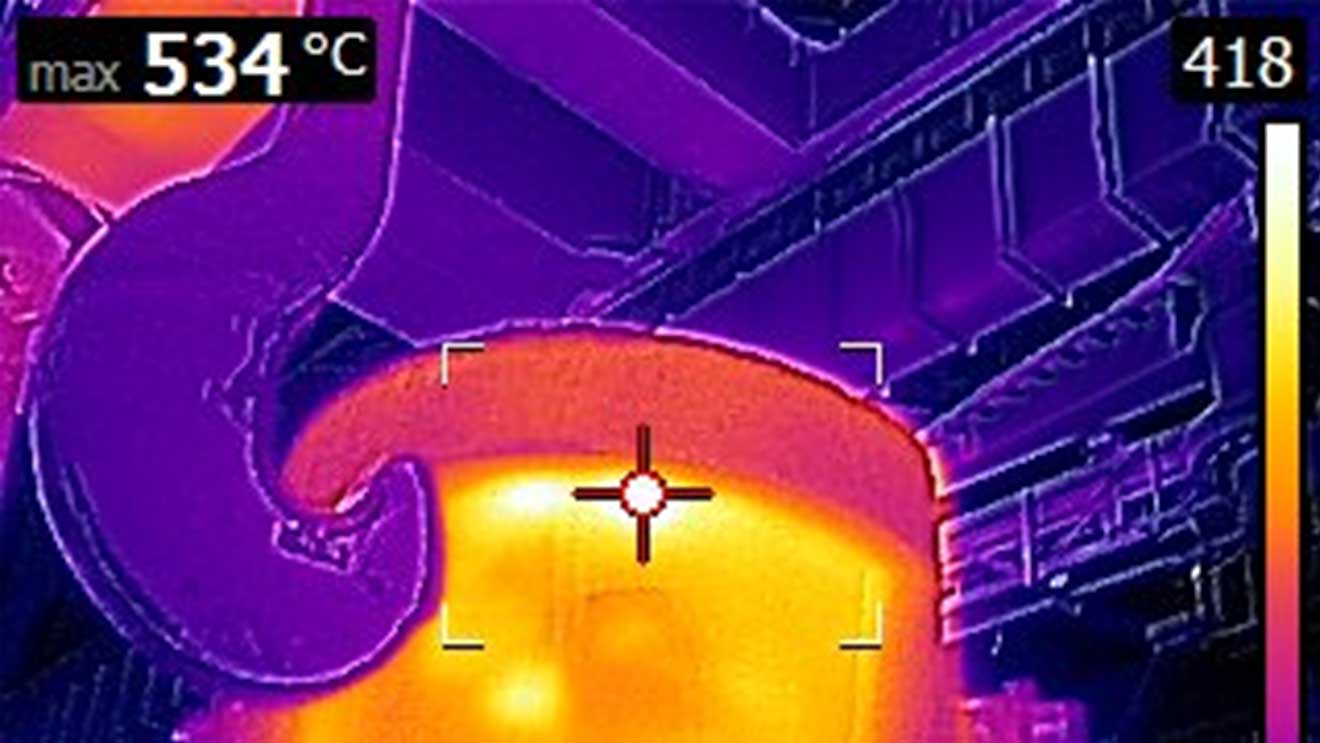

Improving Ladle Lining Stability & Safety

The challenge was to enhance ladle lining stability and safety in secondary steelmaking, addressing hot spots and steel penetration issues.

In secondary steelmaking practices, maintaining ladle lining stability and safety is crucial. Ladle breakouts pose significant risks, including the loss of molten metal and potential injury to workers.

Traditional monitoring practices were insufficient in addressing these issues, leading to frequent ladle failures and increased operational costs.

The need for a more robust solution to enhance ladle lining stability and safety became evident, prompting a comprehensive review of existing practices and the exploration of innovative approaches to improve the performance and reliability of the ladle lining.

Abrasion Reststant Precast Block Flooring

We were tasked with coming up with a design to enable our customer to easily replace the floors outside their furnaces.

We needed to design a precast block flooring system for a melt shop where they repeatedly suffered damage from molten metal spillages, impact and general wear and tear to the areas around the furnaces.

Our customer was experiencing significant unplanned downtime to be able to effect the repairs required and this had a negative impact on their through processing capability.

Having worked with us for more than 30 years our customer could trust that our materials would withstand the test of time and that as a team we would come up with the right solution to suit their needs.