THE CHALLENGE

The client needed to determine the feasibility of producing smaller diameter sticks using the VIM process..

The client, an established manufacturer of large diameter nickel super-alloy ingots using the VIM (Vacuum Induction Melting) process, faced a challenge in producing smaller diameter sticks.

They needed to determine the feasibility of this new manufacturing process.

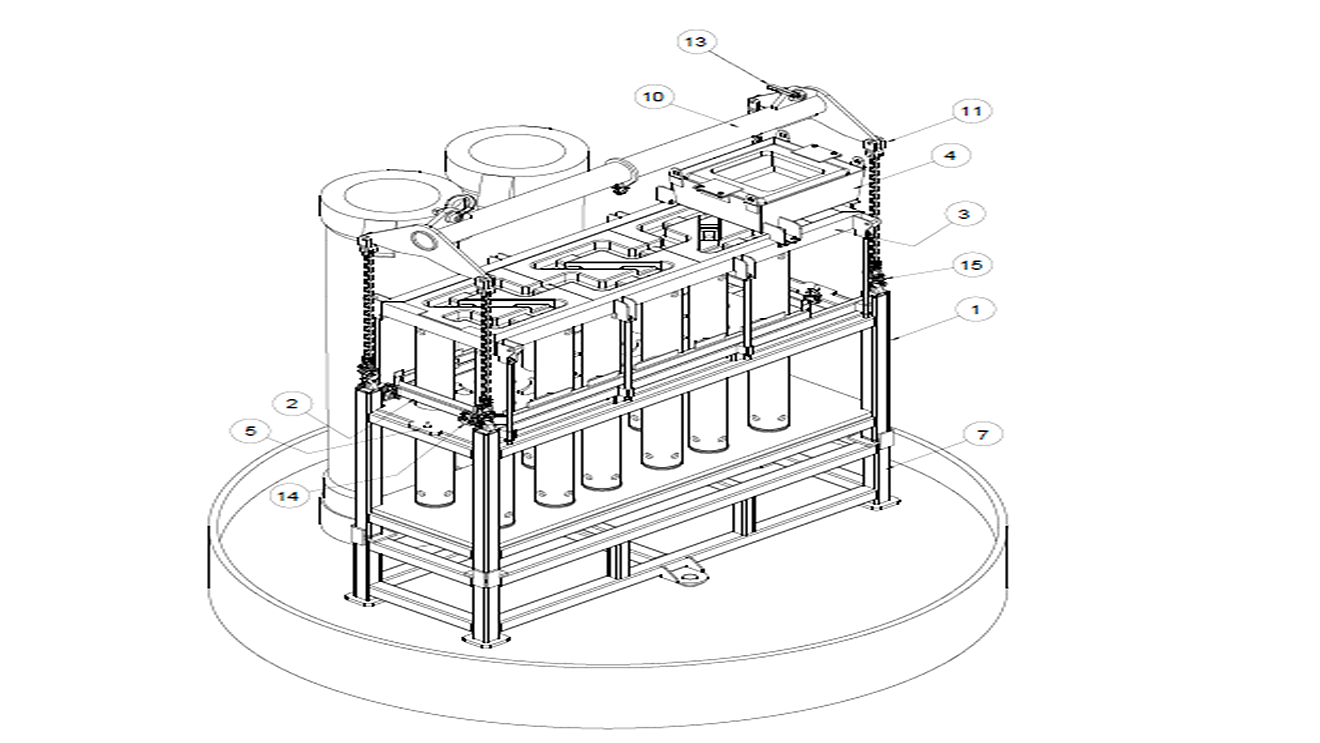

The project required precise material development, engineering, and design of a prototype catcher box.

Additionally, the project had to be completed within a tight timeline of three weeks, which was later extended to four weeks due to unforeseen complexities. The client sought Trent Refractories' expertise to overcome these challenges and ensure the successful execution of the trial.

THE SOLUTION

Trent Refractories collaborated closely with the client to address the challenges.

Project Timeline: The project was initially planned to be completed within three weeks, but the actual delivery took four weeks:

August 29th: Kick-off meeting

September 3rd: Material development completed

September 5th: Design finalised and moulds ordered

September 18th-20th: Items cast

September 23rd-26th: Items fired

November 30th: Trial successfully completed

Despite the extended timeline, the team ensured that all requirements were met.

The engineering and design of the prototype catcher box were meticulously executed, and the material development was tailored to meet the specific needs of the project.

THE RESULT

The trial successfully demonstrated the feasibility of manufacturing smaller diameter sticks, exceeding the client's expectations.

The trial was successfully completed on November 30th, demonstrating the feasibility of manufacturing smaller diameter sticks using the VIM process.

The project not only met the client's requirements but also opened up new opportunities for them to expand their product offerings.

The successful trial showcased the potential for improved manufacturing processes and highlighted the effectiveness of the collaboration between the client and Trent Refractories.

The precise material development, engineering, and design efforts paid off, resulting in a successful outcome that exceeded the client's expectations.

VALUE DELIVERED

The project expanded the client's product range and improved manufacturing capabilities, offering long-term benefits.

The successful completion of the VIM Stick Casting Trial delivered significant value to the client. It provided them with the confidence to pursue the production of smaller diameter sticks, thereby expanding their product range.

The trial also demonstrated the effectiveness of Trent Refractories' expertise in material development and engineering.

The collaboration between the client and Trent Refractories resulted in a streamlined process that can be replicated for future projects.

The value delivered extended beyond the immediate project, offering long-term benefits in terms of improved manufacturing capabilities and potential market expansion.

WHAT OUR CLIENT SAID

We completed the stick casting trial last week using your catcher box. It went really well with no cracking or break-out in the nozzle area.

Jonathan Chambers | Process and Metallurgy Manager, VIM